Industrial Galvanizers – Miami

Project Description:

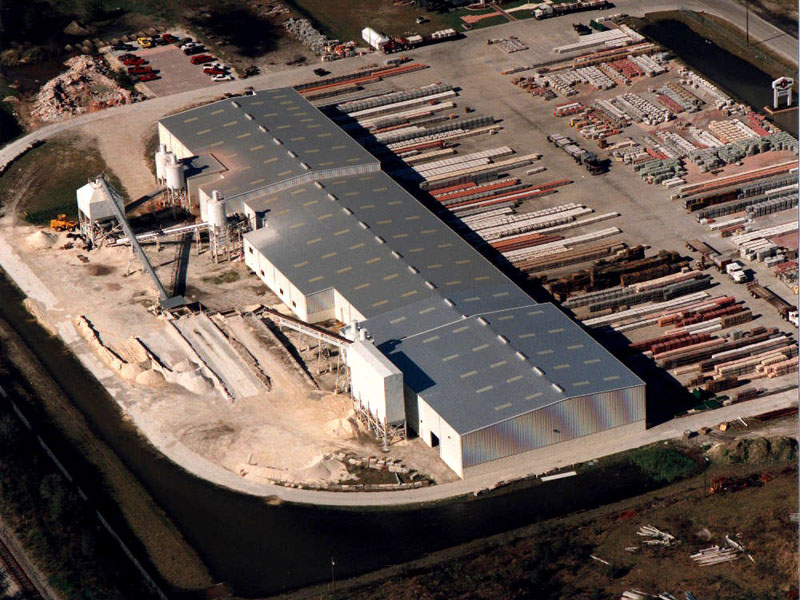

Industrial Galvanizers – Miami is a facility designed for the galvanizing of raw iron and steel materials of all sizes and shapes. The building utilizes numerous bridge cranes for moving both the raw material in and through the building and the finish material out of the building. The raw material moves into the building and commences the process with grease and paint being removed with 180F degree hot alkali solution such as caustic soda and a detergent in large semi recessed tanks. The material is then rinsed and moves to a pickling tank (hydrochloric and sulfuric acid) followed by another rinse. The last stop is a flux solution of zinc ammonium chloride. The material is then moved into the galvanizing chamber and submerged into the molten zinc bath at 840 F degrees. The product is cooled by water or air, depending on product type, inspected for defects, weighed, and stored until ready for shipment or use.

Due to the caustic nature of the process the building is designed with heavy galvanized steel substructure and a concrete tilt wall skin. Ventilation of the building is a prime concern due to the corrosive nature of the vapors from the caustic tanks.

Project Challenge:

The weight of the product being moved by the bridge cranes required consideration for both the dead load and the dynamic load being transferred to the columns. As a result there is a requirement for large column pads. There is an intricate coordination required between the massive column pads and the semi recessed tanks with massive retaining walls. The caustic vapors from the washes requires attention to the ventilation of the building. Concrete tilt wall construction was selected for the skin of the building since the concrete is resistant to corrosion. The roof panels were fiberglass as another precaution to the caustic nature of the vapors. Vertical clearances are critical.

The site in Miami was very tight. Site circulation for semi trailer trucks delivering raw material and picking up finished product was delicate. The delivery of the acid for the caustic washes had to take place in a truck well where any spills could be contained.

Project Details:

Location:

Miami, Florida

Our Valuable Team Members on this Project:

Project Client

Industrial Galvanizers Southeast

Project Representive

Jeff Mattox

Project Manager

Bollenback Builders, Inc.

Structural Engineer

McCarthy and Associates, Inc.

Electrical Engineer

Anston – Greenlees, Inc.

Mechanical Engineer

Anston – Greenlees, Inc.

Plumbing Engineer

Anston – Greenlees, Inc.